Good quality Titanium Threaded Rod – Bright or Galvanized Din976 Threaded Rod – KLT

Good quality Titanium Threaded Rod – Bright or Galvanized Din976 Threaded Rod – KLT Detail:

Making a good threaded rod is no easy task and requires a number of conditions:

1. The screw should be close to sweep the whole screw inner surface, in order to obtain good heat conduction, mixing effect and narrow retention distribution time.

2. The radial clearance between the screw and the barrel (barrel) should be less than 0.003 times the diameter of the screw.

3. Streamlined design is adopted to avoid dead corners.

4. When the plastic contains solid packing particles that need high stress crushing, it is also necessary to choose a dispersed mixing unit. The dispersion mixing unit also ensures that the un-fused plastic particles are not transported to the end of the screw. Thus, dispersion mixing units are useful even if there are no solid filler particles in the plastic.

5. The configuration of the distribution mixing section should be considered comprehensively to reduce the difference of consistency and the non-uniformity of melt temperature. The preferred position of the mixing section is at the end of the screw.

6. When the plastic with dense corrosive packing, such as dioxide corrosion, glass and so on, screw and barrel (barrel) should be made of wear-resistant material.

7. When extrusion PVC, fluorine plastic or other can make exposed gold dust surface corrosion of plastic, screw, barrel (barrel) and machine head application of corrosion resistant materials manufacturing.

8. The mixing section should have low pressure drop and excellent forward pumping capacity.

9. In order to improve the conveying performance of materials and reduce hanging material, the radius of the fillet at the bottom of the thread groove should be larger, and multi-thread and small pitch should be avoided to reduce screw friction and improve conveying capacity.

10. When the screw is coated, the coating with low friction should be given priority. This improves screw delivery performance, resulting in higher yields and better stability, and the screw is easier to clean.

Usage Scenarios: Threaded rod uses include general purpose fastening for anything from an anchor bolt to a through bolt.

Material Style: The material would be as Steel.

Production Process: Normally the finishing could be by Bright, Electronic Galvanized, Hot Dipped Galvanized, Zinc Plated.

Quality Control: Controlled by Interior or exterior relevant parties.

Transaction case presentation: There are many repeat-orders for years.

Transport: The transport could be by Sea or Land.

Delivery: After within 30 days.

Sample: Free Charge.

After-sales: It would be within 60 days.

Payment and Settlement: 30% deposit, 70% balance against the B/L copy within 5 days.

Certification: By ISO or SGS.

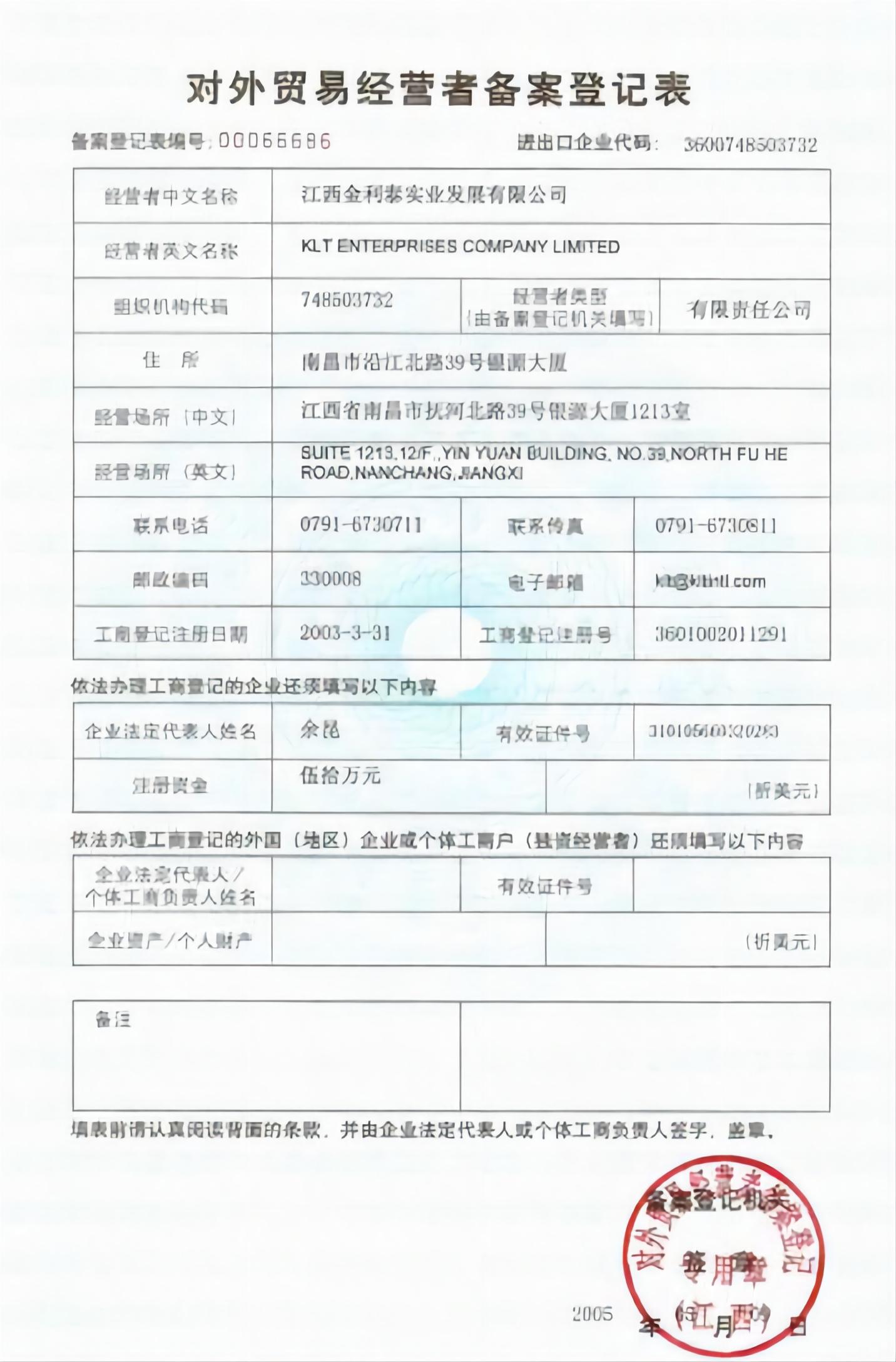

Qualifications

Product detail pictures:

Related Product Guide:

"Quality initial, Honesty as base, Sincere support and mutual profit" is our idea, so as to build repeatedly and pursue the excellence for Good quality Titanium Threaded Rod – Bright or Galvanized Din976 Threaded Rod – KLT , The product will supply to all over the world, such as: Romania, Miami, Roman, We have top engineers in these industries and an efficient team in the research. What is more, now we have our own archives mouths and markets in China at low cost. Therefore, we can meet different inquiries from different clients. Remember to find our website to check more information from our merchandise.

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.