Manufactur standard Full Threaded Rod - Bright or Black or Galvanized Iron Wire – KLT

Manufactur standard Full Threaded Rod - Bright or Black or Galvanized Iron Wire – KLT Detail:

Material Style: The material would be as Q195 or Q235.

Production Process: Wire is made of high-quality low carbon steel wire rod through standard process: wire rod drawing annealed washing galvanized or not coiling quality inspection packing.

Quality Control: Controlled by our professional inspection equipment and department.

Delivery: Usually delivered within 30 days after confirmation of the orders.

Sample: We could supply the samples by free of charge with the post fee collected.

After-sales: Within 30 days after receiving the goods.

Payment and Settlement: 30% deposit 70% payment against the B/L copy within 5 days.

Certification: The certificate should be by ISO or SGS.

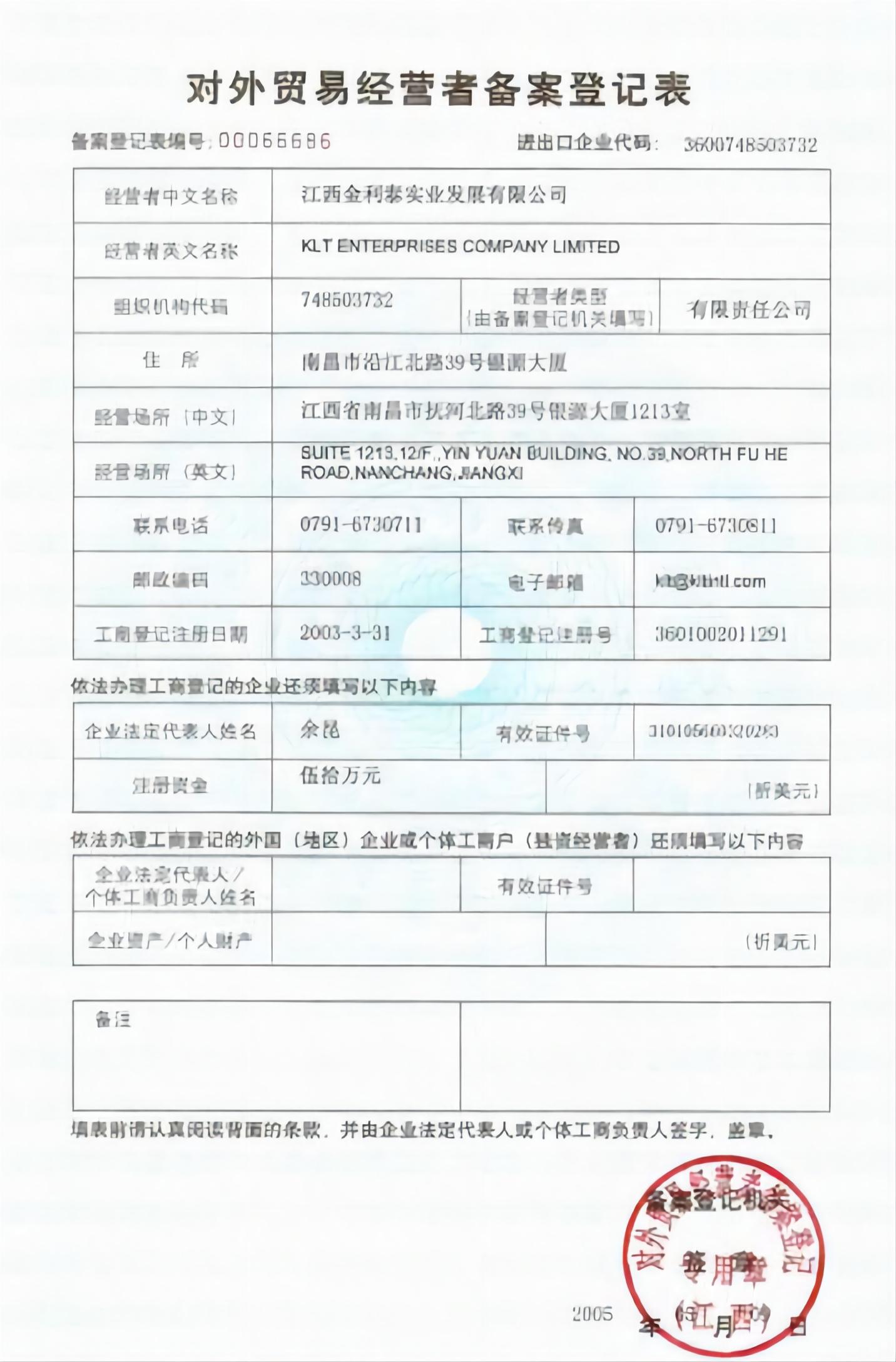

Qualifications

Depending on the thickness of the wire, the equipment used is different. Tank wire drawing machine is generally used for coarse wire drawing, water tank wire drawing machine is practical and middle drawing, fine drawing, numerical control micro drawing machine is suitable for micro wire. The production methods of metal fiber include traditional drawing and cutting method, melting drawing method, cluster drawing method, scraping method, cutting method and so on.

Metal fiber.

The main production methods of metal fiber are: drawing method (cluster drawing method, monofilament drawing), cutting method, fusion beam method.

Drawing method: monofilament drawing and cluster drawing belong to the drawing method, monofilament drawing is the use of metal wire drawing machine, the advantages of high precision, but low cost and efficiency; Cluster drawing is to assemble many stainless steel wires for continuous drawing of many strands. Nowadays, the world’s large-scale production of high-strength ultra-fine metal fiber high-end products of the production enterprises mostly use cluster drawing method.

Cutting method: cutting method mainly includes: milling method, turning method, cutting method, scraping method and so on. It is mechanically cut into metal fibers by equipment or special equipment.

Melting beam method: melting beam method is the earlier production of stainless steel fiber production method, mainly including: crucible melting beam method drawing method, hanging drop melting beam method drawing method, melting wire drawing method. The principle of the beam fusion method is that stainless steel wire is heated to a molten state, and then the molten metal liquid is sprayed or thrown out by a special device and cooled to form the metal fiber .

Product detail pictures:

Related Product Guide:

We are commitment to offer the competitive price ,outstanding products quality, as well as fast delivery for Manufactur standard Full Threaded Rod - Bright or Black or Galvanized Iron Wire – KLT , The product will supply to all over the world, such as: Australia, Ghana, Libya, Due to our strict pursues in quality, and after-sale service, our product gets more and more popular around the world. Many clients came to visit our factory and place orders. And there are also many foreign friends who came for sight seeing, or entrust us to buy other stuff for them. You are most welcome to come to China, to our city and to our factory!

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!